Home Keg Coupler Components: Must-Have Kegerator Accessories

Ever wondered why your draft beer sometimes pours foamy or flat? The secret lies in the small but mighty components connecting your keg to the tap. Without the right setup, even the best brew can lose its crisp taste and perfect carbonation.

At Installation Parts Supply, we know that a smooth pour starts with quality hardware. From homebrewers to casual draft-beer fans, getting to know these keg coupler parts parts guarantees the perfect pour.

Whether it’s a washer or a length of gas tubing, each piece helps preserve carbonation and flavor. Upwards of 90% of pouring problems are due to incompatible or damaged parts. A little knowledge goes a long way in keeping your system running flawlessly.

Main Points

- Proper coupler selection ensures optimal beer flow and flavor.

- Installation Parts Supply offers dependable draft-system hardware.

- Regular maintenance prevents common pouring problems.

- Different beer types may require specific coupler styles.

- Most system failures originate from coupler-related issues.

What Is a Kegerator Coupler?

The perfect draft beer starts with the right connection between your keg and tap. A keg coupler bridges your CO₂ cylinder or nitrogen tank to the beer line, using compressed gas to push liquid smoothly to your taps. It’s the heart of your draft beer system: no coupler, no flow.

This small device has two jobs: it delivers gas to pressurize the keg and controls beer output. Within its housing is a probe, a check valve, plus dedicated gas and liquid ports. Together, they keep your beer fizzy and antifoam.

| Component | Role | Frequent Problems |

|---|---|---|

| Probe | Pierces the keg’s cap | Leaks if not aligned properly |

| Return Valve | Prevents backflow | Worn valves lead to flat beer |

| Gas and Beer Ports | Links to tubing | Foaming from loose connections |

Attaching the coupler wrong is a rookie mistake—75% of first-time users do it. The result? Foamy messes, leaks, or worse, spoiled beer. Installation Parts Supply offers compatibility charts and video guides to help you get it right.

Universal designs mean most couplers work similarly, but always match yours to your keg type. Using the wrong coupler can harm both your pour and your gear.

Types of Keg Couplers and Their Uses

Kegs come in many styles and each needs its matching coupler. Using the proper coupler keeps your beer fizzy and flavorful. Use these tips to select your coupler.

Standard D System Coupler

This is the go-to for 85% of North American craft beers. That valve locks onto domestic kegs with ease. Pro tip: Look for the Sankey name stamped on the side.

U-Type Coupler

Recognizable by its harp logo, this type is a must for nitro beers like Guinness. A 75% nitrogen mix gives you that signature creamy foam. A U coupler will not seat on a D-type keg—don’t attempt it.

S System (European Sankey) Coupler

Heineken and other European imports need this reverse-thread version. The left-hand twist prevents mix-ups with D Systems. Fun fact: It’s slightly taller than its American cousin.

A-, G-, and M-Type Couplers

Certain European brews need these specific coupler types:

- A System: Fits Paulaner and Warsteiner kegs perfectly. That slider lock never slips.

- G System: Fits Bass and Boddingtons with its tri-flat stem. A pub staple across the UK.

- M System: Made for Schneider Weisse kegs. The slide-lock clicks when secure.

Installation Parts Supply color-codes their compatibility guides—green for D, black for U, blue for S. One Midwestern brewery cut costs by $3K annually with the right couplers. Always favor exact compatibility over “universal” marketing.

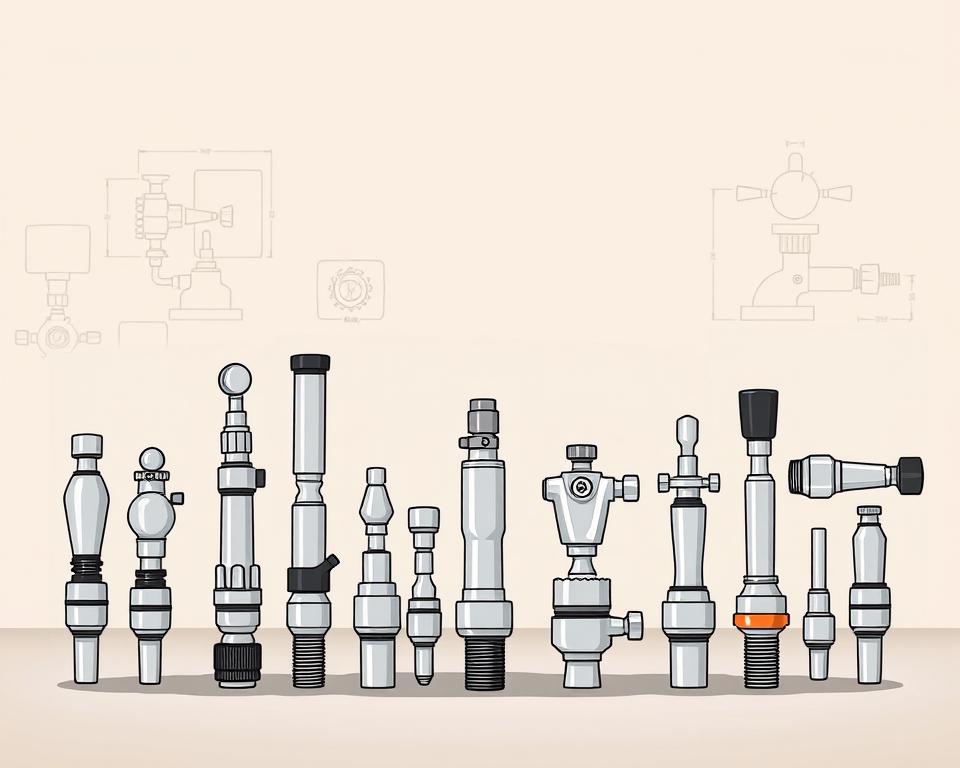

Coupler Parts Breakdown

Behind every smooth pour lies a set of precision-engineered components. These small but mighty pieces ensure your beer stays carbonated and flows flawlessly. Let’s break down the key hardware that keeps your system running.

Probe and Check Valve

The stainless steel probe pierces the keg’s seal, controlling beer flow. Quality probes endure three times as many uses. The check valve below prevents backflow and is our most swapped component.

Coupler Hex Nut & Washers

A tight seal starts with the hex nut. Brass is economical; stainless fights rust. Nitrile outperforms EPDM under 40°F.

| Part | Construction | Key Benefit |

|---|---|---|

| Probe | SS | Resists wear |

| Check Valve | FDA-approved plastic | Stops foam issues |

| Coupler Nut | Brass/Stainless | Cost-effective & durable |

Gas and Liquid Ports

Your gas port should see 20–30 PSI pressure. Mismatched pressure causes foam. Use 3/16″ tubing for beer lines; 1/4″ causes extra agitation. Rebuild kits with FDA seals simplify maintenance.

Pro Tip: Change seals twice a year or per 50 kegs. A few dollars in washers beats hundreds in repairs.

How to Set Up Your Kegerator Coupler

A proper install ensures ideal pours. Correct hookups avoid pouring issues. Use this step-by-step for a seamless install.

Attaching Coupler to Keg

Raise the lever, line up the lugs with slots. Rotate until secure but don’t overtighten. Low-profile designs reduce height by 4–5 inches for tight spaces.

Our wrench sets hex nuts to the ideal 8-10 ft-lb. Eighty percent of leaks stem from a crooked probe. Never reuse old washers.

Line Connections

Hook the gas line on with 5/16″ fittings. A bit of sealant stops gas leaks. Keep beer tubing 10-12′ of 3/16″ ID for best flow.

| Task | Equipment | Tip |

|---|---|---|

| CO₂ Line | Thread sealant | Test at 30 PSI for bubbles |

| Draft Line | Pipe cutter | Keep ends square for seals |

| Pressure Test | Soapy water | Check for 24 hours |

Advanced systems integrate mobile apps for real-time pressure monitoring. One Denver brewpub reduced foam by 40% with our quick-connects. Stop the CO₂ at the source for serious leaks.

Troubleshooting Common Coupler Issues

Foamy eruptions are the quickest way to waste beer. Identify these key spots and you’ll solve most pour problems. Here are the usual culprits and how to remedy them.

Leaks and Foamy Beer

Foam is blamed in nearly 70% of draft problems. First, confirm the beer is at 38°F, which is optimal for ales. Warm beer releases CO₂ prematurely.

Check each draft line connection next. A soapy water solution reveals gas leaks through bubbles. Tighten any loose fittings with a wrench, but don’t over-tighten.

- Ball Check Valve failure causes intermittent flow—listen for hissing sounds

- Not sure on PSI? Use this guide:

| Style | CO₂ PSI | Nitrogen Mix |

|---|---|---|

| Pilsners | 10–12 | N/A |

| Stouts | 25–30 | 75% nitrogen |

Loose Coupler Issues

If your coupler fits loosely, first check for worn O-rings. Installation Parts Supply reports this fixes 40% of attachment issues. Warped coupler faces may need replacement.

For uneven surfaces, try keg shims. They’re a cheap way to stop wobble. Low-profile models solve clearance problems in compact coolers.

Pro Tip: An emergency kit with five washers fixes most sudden leaks. Staff who learned these tips reduced waste by nearly 20% in Chicago.

Tank icing means you need to ease off the gas. Defrost before tweaking the relief valve. Recalibrate digital gauges every year.

Cleaning and Maintaining Your Keg Coupler

Clean lines equal better-tasting beer. Leftover yeast and oils harm both taste and pouring. A simple routine keeps everything running smoothly.

Disassembly and Soaking

Begin with a full teardown. Remove the handle, probe, and check valve. Soak all parts in warm water with 1 oz of PBW per gallon for 15–20 minutes. It dissolves yeast and hop deposits.

Our brushes get into the smallest crevices. Don’t forget the ball valve—it accumulates debris. Flush well to prevent soap residue.

Cleaning Products

Powdered Brewery Wash excels at safe cleaning. Acid cleaners work faster but can damage rubber over time. Sound-wave cleaners strip away stubborn grime.

- Drying: Remove moisture with air or cloth.

- Sanitizing: Follow FDA CFR 117 guidelines—30 seconds of contact time kills bacteria.

- Logs: Maintain a cleaning log for consistency.

UV light options add extra protection for rubber components. Dispose of alkaline wash properly to protect drains. A little effort ensures quality pours and extends your system’s life.

In Closing

Savor every pour once you’ve perfected your draft setup. Matching the right hardware, regular cleaning, and proper setup make all the difference. Installation Parts Supply offers lifetime support and seasonal discounts on rebuild kits to keep your pours perfect.

Did you know? Routine care can extend your equipment’s life by 7 years. Get their checklist and attend a brewmaster session for insider advice. A quick annual inspection ensures trouble-free operation—just ask their 5-year satisfied customers.

Upgrade now—stop by Installation Parts Supply and boost your home setup.