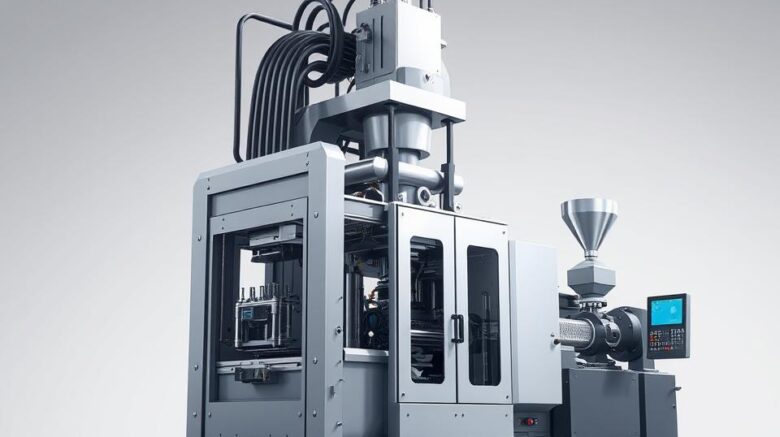

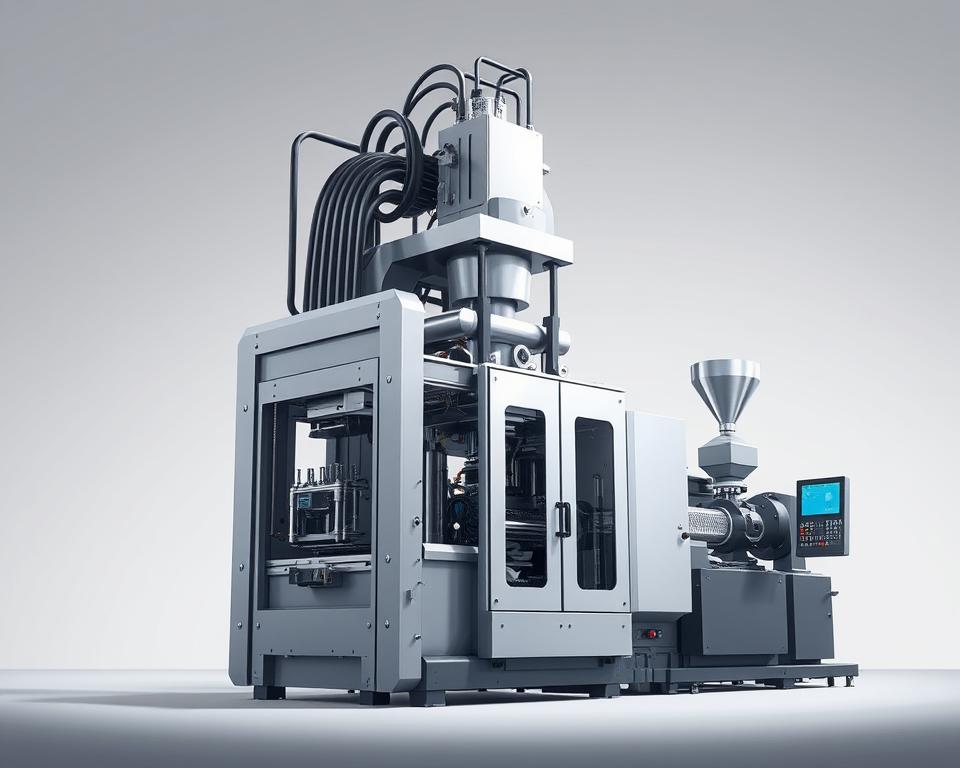

How to Partner with Chinese Injection Molding Companies

The important meeting has recently finished, your new project has the green light, the schedule is tight, and the budget is, let’s say, constrained.. Then someone—maybe your boss, maybe the finance director—utters the phrase that sends a little jolt down every project manager’s spine: “We should look at sourcing this from China.”

Naturally, you agree. On paper, it’s logical. The potential savings can be massive. Yet your thoughts are already spinning. You’ve heard all the horror stories, right? The nightmare of defective parts, opaque communication, and delayed, off-spec shipments. It can feel like you’re being asked to walk a tightrope between landing a huge cost win for the company and steering your project straight into a ditch.

But here’s the catch. Sourcing plastic mold company can be a calculated project. It’s a project, just like any other. And like any project, it succeeds or fails based on the process you follow. It’s not just about the lowest bid but selecting the best partner and overseeing every step. Ignore the nightmare anecdotes. Let’s go through a step-by-step guide to succeed.

Initial Step: Prepare Your Information

Before you even whisper the word “supplier” or open a browser tab to Alibaba, you need to get your own house in order. Truthfully, over fifty percent of offshore sourcing issues originate in an unclear project brief. You cannot expect overseas partners to interpret your unspoken requirements. Sending a vague request is like asking a builder to quote you for “a house.” The responses you get will be all over the map, and none of them will be useful.

Your RFQ should be bulletproof—clear, detailed, and unambiguous. This package is your project’s foundation.

So, what goes in it?

Start with your 3D design files. They cannot be skipped. Stick to universal formats like STEP or IGS to avoid any compatibility headaches. This serves as the definitive part geometry reference.

Yet 3D models don’t cover everything. You also need detailed 2D drawings. This is where you call out the stuff that a 3D model can’t communicate. Examples include tolerances (e.g., ‘25.00±0.05 mm’), material grade, surface finish requirements, and functional callouts. Any seal surfaces or critical hole sizes must be clearly labeled.

After that, material choice. Don’t label it simply “Plastic.” Nor just “ABS.” Be explicit. Specify SABIC Cycolac MG38 in black, if that’s the resin you need. What’s the reason? Because there are thousands of plastic variations. Specifying the exact resin grade ensures you get the strength, flexibility, UV resistance, and color consistency you planned for with plastic mold injection.

A good supplier can suggest alternatives, but you need to give them a clear starting point.

Lastly, add your business data. What is your Estimated Annual Usage (EAU)? They need clarity: is it 1,000 total shots or a million units per annum? Tool style, cavity count, and unit cost are volume-driven.

Finding the Right Supplier

Now that your RFQ is pristine. who will you target? The internet has made the world smaller, but it’s also made it a lot noisier. Locating vendors is easy; vetting them is the real challenge.

You’ll probably kick off on Alibaba or Made-in-China. These are great for casting a wide net and getting a feel for the landscape. Treat them as initial research tools, not final solutions. You’ll want to quickly build a list of maybe 10 to 15 companies that look promising.

But don’t stop there. Think about engaging a sourcing agent. They do cost extra. But a good one has a vetted network of factories they trust. They are your person on the ground, navigating the language and cultural barriers. As a newcomer, this offers priceless security. Think of it as insurance for your project timeline.

Another classic method? Trade shows. If you can attend, shows such as Chinaplas transform sourcing. In-person meetings trump emails. You can handle sample parts, meet the engineers, and get a gut feeling for a company in a way that emails just can’t match. Plus, ask peers for referrals. Tap your professional contacts. A solid referral can be more valuable than any ad.

Shortlisting Serious Suppliers

Now you have your long list of potential suppliers and you’ve sent out your beautiful RFQ package. the quotes will start trickling in. Some prices will undercut logic, others will shock you. Your task is to filter them down to 2–3 credible finalists.

What’s the method? It blends technical checks with intuition.

First, look at their communication. Do they respond quickly and clearly? Can they handle detailed English exchanges? But here’s the real test: Are they asking you intelligent questions? The best firms will question and suggest. For instance: “Draft angle here could improve mold release. Tolerance check via CMM adds cost—proceed?” That’s a huge positive sign. It shows they’re engaged and experienced. A “Sure, no issues” vendor often means trouble.

Next, dig into their technical capabilities. Request their machine list. Review examples of parts akin to your design. Don’t pick a micro-molding shop for large components.

Finally, inspect the factory. This is not optional. Just as you interview hires, audit suppliers. You can either go yourself or, more practically, hire a third-party auditing firm in China to do it for you. They dispatch an on-site auditor for a day. They will verify the company is real, check their quality certifications like ISO 9001, assess the condition of their machinery, and get a general feel for the operation. That small investment can save you thousands.

Converting Digital Designs into Molded Parts

You’ve selected your partner. you’ll agree on terms, typically 50% upfront for tooling and 50% upon first-sample approval. Then comes the real action.

Your supplier’s first deliverable is a DFM analysis. DFM means Design for Manufacturability. It’s their professional review of your CAD. It will highlight potential issues like areas with thick walls that could sink, sharp corners that could cause stress, or surfaces without enough draft angle for clean ejection from the mold. Comprehensive DFM equals a top-tier supplier. It’s a collaboration. You iterate with their team to optimize the mold.

Once the DFM is approved, they’ll start cutting steel to make your injection mold tool. Weeks on, you receive the thrilling “T1 samples shipped” notification. These are the very first parts off the new tool. It’s your first real test.

T1 parts usually require adjustments. That’s standard process. You’ll find minor defects, off-spec dimensions, or finish issues. You’ll provide detailed feedback, they’ll make small adjustments (or “tweaks”) to the tool, and then they’ll send you T2 plastic mold samples. It could require several iterations. Build buffer time for sample iterations.

At last, you get the perfect shot. Dimensions, finish, and performance all check out. This is your golden sample. You ratify it, and it becomes the quality yardstick for production.

Completing the Sourcing Journey

Receiving the golden sample seems like victory, but you’re not done. Now you’re entering the mass production phase. How do you maintain consistency for part 10,000?

Implement a robust QC plan. This often involves a pre-shipment inspection. Bring in an external QC firm. They’ll randomly select parts, compare them to specs and golden sample, and deliver a detailed report. They provide a photo-filled inspection report. After your approval, you release the shipment and final funds. This step saves you from a container of rejects.

Finally, think about logistics. Clarify your Incoterms. Are you on FOB terms, where they load and you take over? Or EXW, where you handle everything from their gate? Your Incoterm selection drives landed expenses.

Sourcing from China is a marathon, not a sprint. It hinges on strong supplier relations. View them as allies, not vendors. Open dialogue, trust, and rigorous procedure deliver results. It’s a challenging project, no doubt. But with this framework, it’s one you can absolutely nail, delivering the cost savings everyone wants without sacrificing your sanity—or the quality of your product. You’re set to succeed.