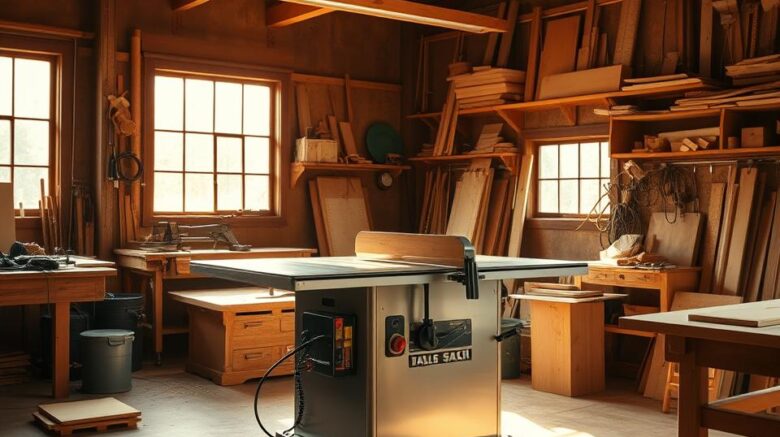

Samach: Furniture Woodworking Machinery Experts

Have you ever wondered what it requires to transform uncooked materials into premium finished products? The solution is found in accuracy, ingenuity, and the correct implements. Samach is at the vanguard of this sector, providing reliable approaches for modern manufacturing requirements.

With years of expertise, Samach has become a premier brand in the arena. Their cutting-edge woodworking machine are engineered to provide unmatched exactness and efficiency. Whether you’re a professional or a hobbyist, their systems guarantees every assignment satisfies the most rigorous benchmarks.

Spanning state-of-the-art apparatus and steadfast backing, Samach supplies all you require to thrive. Explore further details on their creative approaches by checking out www.samach.cn. This piece will guide you through the crucial aspects of their provisions, helping you make informed decisions for your tasks.

Overview of Samach and Home Furnishing Machinery

Accuracy and creativity are the pillars of modern production, and Samach masterfully offers both. With decades of experience, Samach has grown into a dependable moniker in the carpentry sector, offering advanced solutions for professionals and hobbyists alike.

Samach’s expertise lies in combining time-honored artistry with cutting-edge technology. Their carpentry equipment are built to satisfy the most rigorous benchmarks of accuracy and efficiency. Whether you’re working on small projects or large-scale production, Samach delivers the equipment essential for achievement.

Samach’s Background and Expertise

The evolution of Samach started with an emphasis on excellence and creativity. Now, they are recognized worldwide in the carpentry equipment industry. Their team of experts ensures every product is built to last, offering reliability and performance that professionals trust.

Spanning CNC routers through edgebanders, Samach’s catalog serves multiple demands. Their devices are built to tackle complex tasks with ease, making them a top choice for the woodworking industry.

Online Presence and Dependable Solutions

For further details regarding Samach’s state-of-the-art answers, check out www.samach.cn. Their online platform delivers in-depth details about their catalog, customer support, and global showroom locations. Samach’s focus on superior standards establishes them as a reliable ally for experts globally.

| Characteristic | Specification |

|---|---|

| RPM Spectrum | 12,000 to 18,000 r/min |

| Work Speed Range | 1 up to 15 m/min |

| Maximum Cutting Length | 3,100 mm |

| Main Saw Motor Power | 5.5KW |

| Warranty Period | 1 Year |

Samach’s machines are backed by industry-leading warranties and ISO 9001 certification. Their worldwide reach spans countries like Vietnam, Brazil, South Korea, guaranteeing availability to clients globally.

Steering Through Woodworking Apparatus

Spanning simple implements to high-tech systems, woodworking machines present varied answers for every project. Whether you are experienced or just starting out, comprehending the distinctions between manual and robotic machinery is key to success.

Overview of Manual and Automatic Machinery

Manual equipment, for instance wood lathes, necessitates active operation and is perfect for minute, precise tasks. They ensure exactness, though they call for extra effort and duration. On the other hand, automatic systems, such as CNC machines, streamline production with minimal human intervention. These are perfect for large-scale projects and complex designs.

Key differences include:

- Hand-operated devices are economical yet less speedy.

- Robotic systems boost productivity and uniformity.

- Both types cater to different needs in the woodworking industry.

Essential Attributes and Advantages for Carpenters

Premium devices are marked by their exactness, simplicity of operation, and versatility with different media. Cutting-edge innovations guarantee uniform outcomes, even when working with hardwood. For instance, CNC systems grant peerless exactness, whereas wide belt sanders render flawless surfaces.

Gains involve:

- Enhanced output and minimized scrap.

- Enhanced safety features for operators.

- Flexibility for changing task demands.

The woodworking industry continues to embrace innovative materials and technology, making modern machinery more reliable and efficient than ever.

Guide for Choosing the Best Woodworking Devices for Furniture Crafting

Selecting the proper tools is the initial move to obtain impeccable outcomes in every task. Be it constructing cabinets or managing intricate layouts, the instruments employed can transform your output. This guide will enable you to grasp the types of equipment available and how to evaluate their quality for your needs.

Understanding Different Equipment Types

From planing machines to joinery equipment, there’s a wide range of tools designed for specific tasks. Every category fulfills a specific role in manufacturing. For instance, surface planers excel at evening out textures, while joinery systems guarantee accurate linking of elements.

Here is an outline of standard machinery types:

- Planing Machines: Perfect for flattening and smoothing surfaces.

- Assembly Devices: Ensures accurate and durable connections.

- CNC Machines: Perfect for complex patterns and extensive manufacturing.

Measuring the Caliber of Machinery

Choosing premium equipment is vital for reliable outcomes. Look for features like durability, precision, and ease of maintenance. A well-built machine not only enhances production but also reduces downtime and repair costs.

Take into account the following benchmarks:

- Durability: Check the build quality and materials used.

- Accuracy: Confirm that the device produces exact performance reliably.

- Simplicity of Upkeep: Select devices that are simple to maintain and fix.

By evaluating these factors, you can invest in machinery that meets your project requirements and delivers long-term value.

Essential Accessories and Technological Advances

Within the constantly changing realm of manufacturing, supplementary parts and advanced tech are vital for boosting productivity. Ranging from breakthrough belting methods to high-tech automation, these parts are reshaping operational dynamics. This section examines the transformative technologies molding tomorrow’s production.

Advanced Belt Technologies and Side Finishing

Belting solutions like trailroll belts and sandbelts are revolutionizing machine accuracy. Such add-ons guarantee seamless functioning, notably in processes like edge banding. In particular, accessories for edge banding deliver exact completions, thereby being critical for superior output.

Dedicated feeding mechanisms and metallic parts boost robustness further. For instance, rubber alongside metal rollers is crucial for sanding operations and precise calibration. Such components maintain uniform functionality, regardless of challenging settings.

Leveraging CNC, Lathes, and Other Tech

Computerized numerical control systems and lathes lead the wave of modern innovations. CNC systems automate complex tasks, reducing manual labor and increasing precision. In contrast, turning machines are indispensable for creating homogeneous components, augmenting design and utility.

These technologies integrate seamlessly with other components, ensuring every piece is processed optimally. From planing machines to brushing systems, each part contributes to a streamlined production process. Ultimately, it leads to substantial enhancements in both performance and output.

Adopting these breakthroughs renders manufacturing more dependable and productive. Whether it’s through advanced belting solutions or automated systems, technology continues to push the boundaries of what’s possible.

Market Dynamics and Novel Developments in Woodworking Devices

The carpentry equipment arena is experiencing major shifts propelled by tech advancements and consumer trends. Boasting a worldwide value of USD 4.86 billion in 2023, projections indicate growth to USD 7.77 billion by 2032. This growth is fueled by advancements in machines and the increasing adoption of innovative materials.

Consequences of Global Economic Trends and COVID-19

The COVID-19 pandemic temporarily disrupted production and sales, causing delays in supply chains. However, the industry adapted quickly by integrating digital solutions and smart manufacturing technologies. For example, companies like SCM Group enhanced their service offerings to meet evolving customer needs.

International market trends have likewise impacted the need for woodworking machinery. With a 40.53% market portion in 2023, Europe persists as a leader because of its commitment to eco-friendly methods. In contrast, the Asia-Pacific area is anticipated to achieve the steepest growth, propelled by expanding populations and improved earnings.

Innovations and Outlook for the Future

Technological advancements are shaping the future of the industry. Automated CNC systems and machines are setting the norm by providing exactness and effective operation. Such breakthroughs are especially advantageous for extensive production and intricate projects.

Emerging substances like Cross-Laminated Timbers (CLTs) are becoming increasingly favored. These materials are not only sustainable but also enhance the durability and functionality of products. Thus, manufacturers are channeling investments into machinery adept at managing such cutting-edge materials.

| Industry Shift | Outcome |

|---|---|

| Embracing CNC Systems | Boosted exactness and output |

| Rise of Sustainable Materials | Enhanced product durability |

| Surge in the Asia-Pacific Market | Expanded market opportunities |

Projecting forward, the market is set for more inventive developments. Customer demands for customization and sustainability will continue to drive advancements. Adopting these shifts enables producers to remain ahead and satisfy the demands of an ever-changing industry.

Optimizing Production with Precision and Industrial Solutions

Productivity and precision power today’s manufacturing processes. In order to secure uniform results, the industry turns to cutting-edge machines and meticulous processes. This section investigates the integration of advanced approaches to refine processes and boost product excellence.

Precision Milling, Edgebanding, and Cabinet Making

Accurate milling is vital for crafting detailed motifs and achieving homogeneity in every piece. State-of-the-art CNC methods streamline the operation, cutting down inaccuracies and increasing velocity. Such machines are especially important in cabinet fabrication, where precision is paramount.

Trim application, a further key operation, secures flawless outcomes and resilience. Contemporary edge banding equipment incorporates custom feed mechanisms for steady performance. This technology is indispensable for high-quality production, especially in custom projects.

For cabinet making, precision equipment like CNC routers and joinery machines are game-changers. They handle complex designs with ease, ensuring every component fits perfectly. Such precision reduces scrap and boosts productivity.

Methods for Improved Output

Incorporating exact components and modern feeding mechanisms can markedly enhance production processes. They guarantee seamless functioning and cut back on idle periods. For example, automated feed systems maintain consistent material flow, enhancing overall efficiency.

Another strategy is leveraging high-tech machinery for repetitive tasks which not only speeds up production but also ensures uniformity across all pieces. Automating operations allows companies to direct efforts toward maintaining quality and fostering innovation.

The Significance of Accuracy for Quality Control

Exactness is the foundation of quality control in production. Advanced machines ensure every cut, drill, and finish meets exact specifications. This degree of exactness is essential to uphold lofty standards and consumer anticipations.

As an illustration, CNC technologies permit precise programming, guaranteeing optimal processing of every piece. This reduces errors and enhances the final product’s durability and functionality. Precision equipment also minimizes material waste, contributing to cost savings.

Adopting meticulous techniques and modern innovations enables producers to refine their production processes. This approach enhances operational output while assuring that every task reaches premium standards.

Concluding Reflections and Future Directions for Carpentry Mastery

Reaching peak quality in manufacturing demands proper equipment, accuracy, and an innovative mindset. Throughout this article, we’ve explored how advanced machines and innovative solutions can transform your projects. Whether it’s computerized systems or dedicated equipment, the optimal tools guarantee effective and high-caliber outcomes.

For your next move, think about incorporating premium machines into your operations. Check out www.samach.cn for customized offerings and professional assistance. Their commitment to precision and reliability makes them a trusted partner in the industry.

Welcome the freshest developments and match your project targets with state-of-the-art solutions. By focusing on continuous improvement and leveraging the right service, you can achieve outstanding results. Let innovation drive your success and elevate your production to new heights.